Retrofitting for Sound: The Pro Playbook to Upgrade Floors to Part E Performance

When you convert, refurbish, or just want peace between flats, one upgrade makes or breaks the project: turning a noisy separating floor into a Part E–compliant acoustic system. This combined guide gives you the big picture (what the regs actually demand) and a ready-to-build specification you can lift onto drawings including layer-by-layer make-ups, sequences, and QA checkpoints.

What “Part E performance” really means

UK Building Regulations Approved Document E (ADE) sets minimum on-site performance for separating floors using two single-number quantities:

- Airborne sound (voices, TV): DnT,w + Ctr higher is better

- Impact sound (footfall): L′nT,w lower is better

Minimum targets in England (dwellings):

- New build (purpose built): Floors and stairs DnT,w + Ctr ≥ 45 dB and L′nT,w ≤ 62 dB

- Material change of use (caonversions): Floors and stairs DnT,w + Ctr ≥ 43 dB and L′nT,w ≤ 64 dB.

ADE also makes clear that you’re judged on the whole element plus its flanking construction not just the main leaf which is why junctions and detailing matter.

Compliance routes (and which one applies to you)

There are two common ways to demonstrate compliance:

- Robust Details (RD) for new attached dwellings only. If you register and build an approved RD floor detail, you don’t do pre-completion tests for that plot type.

- Pre-Completion Testing (PCT) the default route, especially for conversions, where RD registration isn’t available. Tests measure DnT,w + Ctr and L′nT,w across representative rooms and record the results in the handover report.

For context and official summaries, see the Planning Portal’s current ADE overview.

What gets tested (and when)

Accredited testers (UKAS and/or ANC-registered) carry out airborne and impact tests to ADE procedures and issue a formal report listing the rooms, measured single-number quantities and pass/fail.

Diagnose before you prescribe

Map the weak links before choosing products:

- Floor type: Timber joists with boards? Concrete slab?

- Cavity: Depth, existing insulation, open voids?

- Ceiling: Direct-fix plasterboard vs. resiliently suspended? Downlights?

- Flanking paths: Lightweight partitions, continuous floorboards under walls, service risers, chimney breasts, perimeter gaps. (ADE performance is on-site and includes flanking.)

Proven upgrade paths for existing floors

Below are field-tested approaches with increasing performance and programme implications. Mix and match to suit structure, headroom, fire, and services.

Path A - Overlay-only (fastest when you can’t open the ceiling)

Build-up (typical timber floor):

- Seal existing boards (fill gaps, perimeter mastic)

- Lay a resilient acoustic underlay (rubber/foam composite, taped seams)

- Add a floating mass deck (e.g., 18–22 mm gypsum-fibre or chipboard) with 5–10 mm isolated perimeter upstand

Why it works: The resilient layer reduces impact at source; the extra mass nudges airborne. Overlay systems are a recognised route for timber floors where the existing deck remains in place.

Reality check: Overlay-only upgrades reliably tame L′nT,w. For a comfortable airborne margin, you usually also decouple the ceiling.

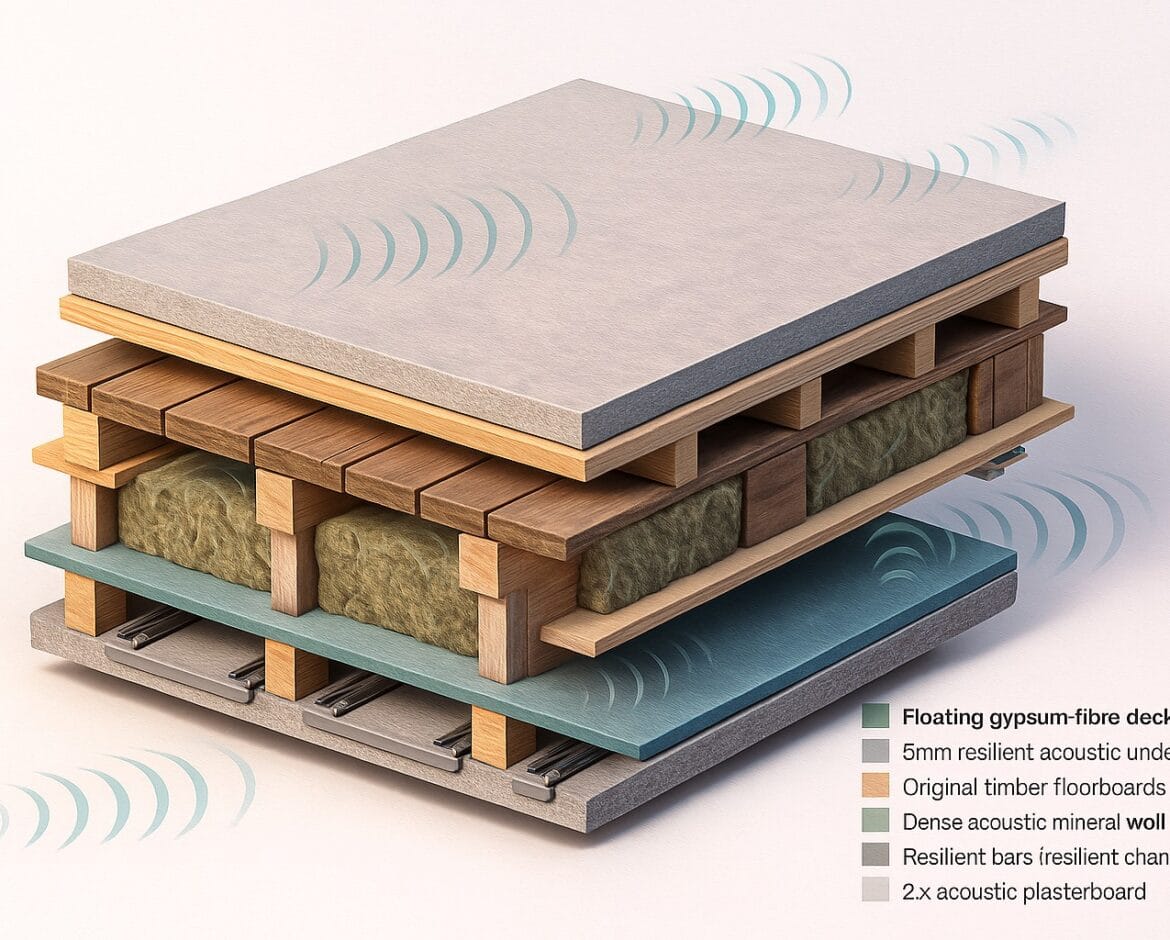

Path B - Overlay + resiliently suspended ceiling (the retrofit sweet spot)

Add to Path A:

- Friction-fit acoustic mineral wool (≈ 45 kg/m³) between joists (don’t overpack)

- Fix resilient bars/MF ceiling below; line with 2 × 12.5–15 mm acoustic plasterboard; stagger joints; perimeter seal

Why it works: You’re combining mass + absorption + decoupling, which is how you turn a borderline pass into a robust one under site conditions. (Resilient bar systems are specifically intended to decouple boards from joists for better isolation.)

Path C - Independent ceiling + high-mass floating deck (for tough conversions)

Free-standing MF/clip-and-channel ceiling with 2 × 15 mm boards; full-depth mineral wool; high-mass floating deck above; rigorous perimeter isolation and airtightness. Use when the base build is poor or you want comfortable test margins.

Concrete slabs (1960s–1990s blocks and many newer builds)

Concrete usually passes airborne; impact is the problem. The straightforward remedy is a floating/resilient layer above (or a resiliently suspended ceiling below if airborne is marginal). ADE/Welsh guidance explicitly notes that floating floors reduce impact sound at source.

See also acoustic design notes on improving concrete floors with screeds on resilient layers or acoustic overlays.

Detailing: the difference between a pass and a retest

- No perimeter bridges. Keep 5–10 mm gaps at floor and ceiling perimeters; install resilient upstands; seal after finishes.

- Resilient bars done right. Bars run perpendicular to joists; boards fix to bars only; screws must not touch joists (avoid short-circuiting). Typical centres 400–450 mm for ceilings.

- Services & penetrations. Sleeve and seal; fit putty pads to sockets; use fire/acoustic hoods to downlights; don’t let services bear on bars.

- Flanking control. If lightweight party-side walls limit results, line them on bars or independent studs with 1–2 board layers. (ADE treats floors along with their associated flanking constructions.)

The tailored, ready-to-build spec (assumed common UK conversion)

If your project differs (no ceiling access / concrete slab / shallow joists), see variants below.

Assumptions:

1950s–80s conversion; timber joists ~47×200 mm @ ~400 mm c/c, original 18–22 mm T&G deck; existing direct-fix 12.5 mm ceiling; downlights; access above and below. Target: Part E conversion 43/64 (on-site).

A) Final build-up (from top down)

Floor (above):

1) Finish (by others) over2) 8–10 mm high-density acoustic underlay (taped seams)3) 22 mm gypsum-fibre T&G floating deck (or 18–22 mm P5 + 6 mm cement-fibre overlay), 5–10 mm perimeter clear with resilient upstandJoist zone:

4) 100 mm acoustic mineral wool ≈ 45 kg/m³, friction-fit

Ceiling (below):

5) Resilient bars @ 400 mm c/c, perpendicular to joists

6) 2 × 15 mm acoustic plasterboard, joints staggered; perimeter sealed with acoustic sealant

Why this mix: Underlay + floating deck addresses impact at source, the decoupled ceiling drives airborne performance, and wool damps cavity modes the classic mass-air-mass system optimized for site. (Resilient bar systems are designed to decouple boards from structure.)

Added thickness (guide): ~30 mm above, ~50–60 mm below.

Programme tip: Always do one pilot room, then roll out.

B) Materials schedule (brand-neutral)

- Underlay: 8–10 mm resilient acoustic layer (low dynamic stiffness for hard floors)

- Floating deck: 22 mm gypsum-fibre T&G (or chipboard + cement-fibre overlay)

- Perimeter isolation: 5–10 mm resilient strip, 75–100 mm upstand

- Cavity insulation: 100 mm mineral wool ≈ 45 kg/m³

- Ceiling: Resilient bars + 2 × 15 mm acoustic board; acoustic sealant; putty pads; downlight hoods

C) Fixing patterns & must-dos

- Bars perpendicular to joists; never screw boards into joists through the bar; typical 400–450 mm bar centres for ceilings; stagger board joints; seal perimeters.

- Keep 5–10 mm isolation gaps at floor deck and ceiling edges; back-seal after finishing.

- Box services on separate framing; no loads on bars.

D) Quantities (per 10 m² floor area - rule of thumb)

- Underlay: ~10.5 m² (incl. 5% waste)

- 22 mm GF boards: ~10.5 m²

- Isolation strip: room perimeter (≈ 3.8 × √Area → ~12 m)

- Mineral wool: ~1.0 m³

- Resilient bars: ~30 lm

- Boards to underside: ~21 m² (two layers + waste)

- Screws: ~600–700 total; sealant: 2–3 cartridges

E) Method statement (sequence that works on site)

- Survey joists, services, flanking; mark centres

- Topside: seal board gaps; fit isolation upstand; lay/tape underlay; float deck with 5–10 mm perimeter gap

- Below: strip old ceiling; reinstate cavity barriers; friction-fit wool

- Fix resilient bars @ 400 mm c/c; no short-circuiting

- Board 1; putty pads; hoods; perimeter seal

- Board 2 (staggered); perimeter seal; skim

- Re-fix skirtings without crushing upstand; final seals

- PCT prep: doors hung, windows sealed, services complete; proceed to testing per ADE Annex B.

Variants (if your site differs)

- No access below (overlay-only): Use a high-mass floating deck over resilient underlay with strict perimeter isolation to tackle impact; expect smaller airborne gains without a decoupled ceiling; treat flanking walls if needed.

- Concrete slab: Prioritise a resilient layer/floating floor for impact; add a resiliently suspended ceiling if airborne is marginal.

Advanced acoustics in one minute

- Mass-air-mass: Boards + cavity + boards create a resonance you push lower with more mass and deeper, absorptive cavities

- Decoupling: Resilient bars (or clips) reduce structural coupling, improving both airborne and impact performance (when paired with a soft layer at source)

- Flanking: Treat the weakest path junctions and side walls often set the ceiling on site performance. ADE’s targets apply to the whole construction including flanking.

Pre-completion testing: quick expectations

Tests follow ADE procedures and report DnT,w + Ctr and L′nT,w values for each source receiver room pair. Using UKAS/ANC-accredited providers aligns with ADE guidance and Building Control expectations.

Quick QA checklist (print for site)

5–10 mm perimeter isolation at floor and ceiling; sealed after finishing No screws through bars into joists; bars at 400–450 mm centres; boards staggered 100 mm mineral wool present; not overpacked Putty pads to sockets; downlight hoods fitted; sleeves sealed both layers Floating deck truly floating; no perimeter bridges Flanking walls assessed; lined if needed PCT booked with UKAS/ANC tester; rooms test-ready.References & further reading

- Approved Document E (official PDF with performance tables & testing): targets and Annex B testing notes.

- Planning Portal summary of ADE (current edition & scope): handy orientation.

- Robust Details (official site): alternative to PCT for new attached dwellings only.

- UKAS/ANC info on accredited sound insulation testing: competence & recognition.

- Concrete floors & floating layers reduce impact at source (guidance): ADE/Welsh doc section on floating floors.

- Overlay systems for timber floors (context): practical retrofit approaches.

- Resilient bar installation essentials: centres, perpendicular fixing, no short-circuiting.

FAQ

Do I have to remove the existing ceiling to pass Part E?

Not always. Overlay-only upgrades often improve impact significantly; adding a resiliently suspended ceiling typically provides the margin needed for airborne performance on timber joist floors.

Can I use Robust Details on a conversion?

No. The Robust Details scheme is for new attached dwellings; conversions generally follow the PCT route.

What exact numbers do I need to hit on site?

For new build floors/stairs: DnT,w + Ctr ≥ 45 dB, L′nT,w ≤ 62 dB. For conversions: DnT,w + Ctr ≥ 43 dB, L′nT,w ≤ 64 dB (England)